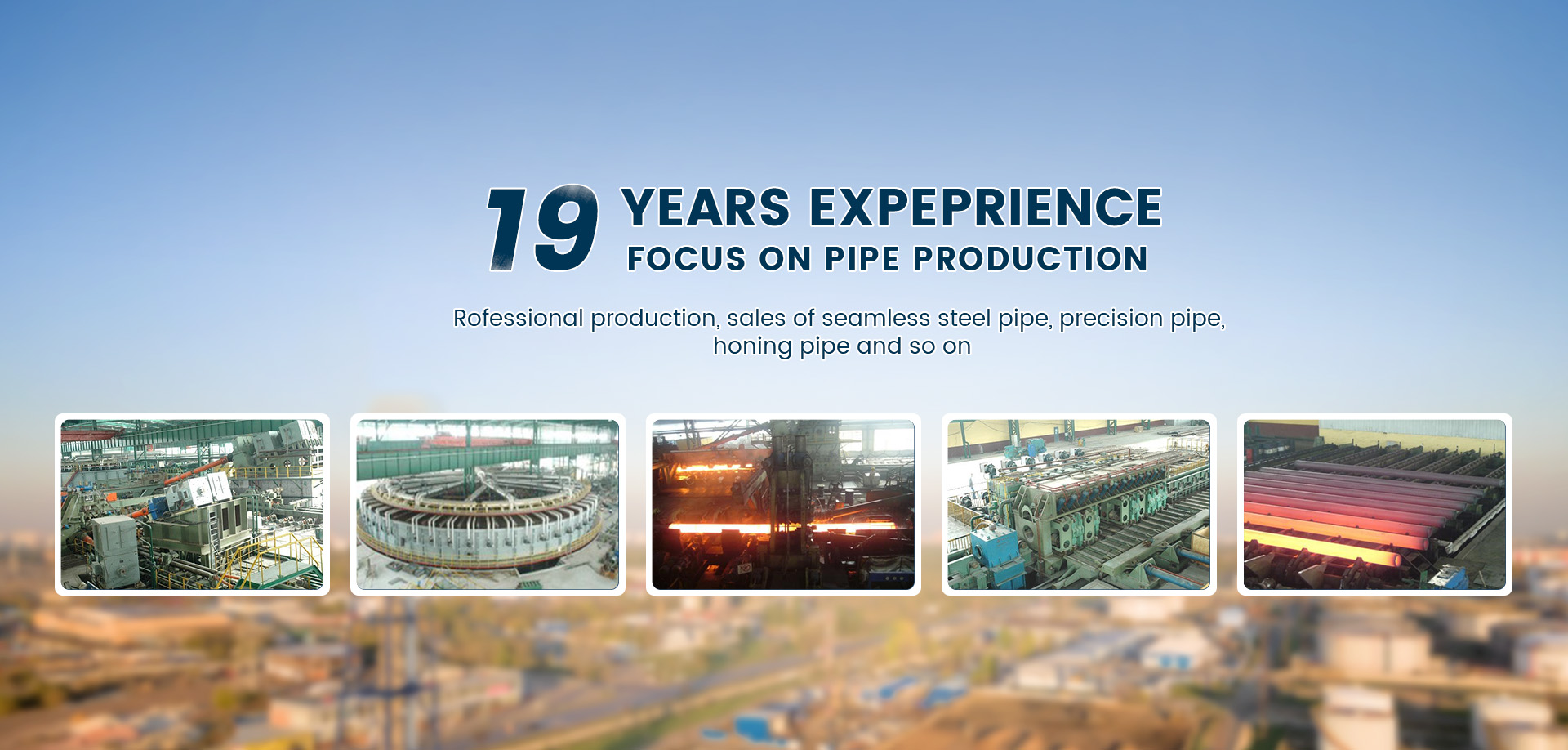

ABOUT US

LIAOCHENG XINGLONG

Liaocheng Xinglong Seamless Steel Tube Manufacturing Co., Ltd is founded in 2004, Covering an area of 15000 square meter. And the total asset is above 250 million Yuan. There are 850 staff members including 180 technicians in our company. Annual output is 60,000 tons. We also establish an effective complete quality control system . In 2006, our company obtained the authorization of ISO9001 Quality System. And it started to run in accordance with API 5L and API 5CT in 2009.

- VR

Honed Tubes are a type of steel tube that undergoes a precision honing process, commonly utilized in various industries such as automotive, hydraulic, and pneumatic systems. Product AttributesProduct name:Hydraulic Cylinder TubeLength :3-12MOD: 32-710mmWT:2-80mmProduction Process:Cold…

seamless steel pipe has become an essential component across numerous industries due to its exceptional strength, reliability under extreme conditions,and cost-effectiveness. It continues playing a vital role in facilitating transportationof fluids,gases,and other substances safelyand efficiently…

One of the key features of Precision Steel Tubes is their precise dimensions. These tubes have accurate outer diameters, wall thicknesses, and lengths, which make them suitable for applications where tight tolerances are required. Key attributesProduct name:Precision steel tubeSection Shape:…

Carbon seamless steel pipes have several key characteristics that make them highly desirable. Firstly, they have uniform wall thickness throughout the entire length of the pipe, ensuring consistent performance under different operating conditions. Secondly, they offer superior strength compared…

01

Seamless steel pipe introduction

Seamless steel pipe is a type of steel pipe that is manufactured without any welding seam or joint. It is made by piercing a solid billet of steel to form a hollow tube, which is then further processed through various manufacturing techniques to achieve the desired dimensions and properties. seamless steel pipe offers numerous benefits including strength, durability, corrosion resistance, versatility, and reliable performance across diverse industries. Its seamless nature eliminates weak points associated with welded joints while providing efficient fluid transportation capabilities under demanding conditions.

02

Seamless steel pipe Application

(1)Alloy pipe:The seamless steel pipe features resistance to high pressure,high/low temperature and corrosion and is used in the industries of petroleum,chemical engineering and electric power as well as boiler.(2)Temperature-resistant seamless steel pipe for high-pressure boiler.(3)Boiler pipe for refinery,heat-exchanging pipe,seamless steel pipe for pipeline.(4)Fertilizer making equipment and pipe line.(5)Over-heat pipe for low-and medium-pressure boiler,boiling water pipe,locomotive smoke pipe (big and small).(6)Fluid feeding.(7)For common structure.(8)Carrying gas,water or oil in the industries of petroleum and natural gas.

03

Precision steel pipe introduction

Precision steel tube is a type of high-quality steel pipe that is manufactured with precise dimensions and tolerances. It is widely used in various industries such as automotive, aerospace, construction, and machinery.One key characteristic of precision steel tubes is their accurate dimensions. These tubes are produced using advanced manufacturing techniques to ensure tight dimensional control. This precision allows for seamless integration into different applications where accuracy and reliability are crucial.Another important feature of precision steel tubes is their excellent mechanical properties. They possess high strength, durability, and resistance to corrosion. These qualities make them suitable for demanding environments and applications that require reliable performance under extreme conditions.Precision steel tubes also offer superior surface finish compared to other types of pipes. The smooth inner and outer surfaces minimize frictional losses during fluid flow or heat transfer processes. This attribute enhances the efficiency of systems utilizing these tubes while reducing energy consumption.Furthermore, precision steel tubes can be customized according to specific requirements. Manufacturers can produce them in various shapes, sizes, grades, and finishes to meet diverse application needs. This versatility makes them highly adaptable across different industries.

04

Precision steel pipe Application

For manufacture of mechanical structure、hydraulic pressure equipment.hydraullc pressure and cylinder.

05

Honed Tube introduction

Honed Tubes are a type of steel tube that undergoes a precision honing process, commonly utilized in various industries such as automotive, hydraulic, and pneumatic systems. The honing process involves the use of abrasive stones to eliminate any imperfections on the inner surface of the tube, resulting in a smooth and polished finish. One significant advantage of Honed Tubes is their enhanced dimensional accuracy and surface quality compared to regular tubes. This makes them suitable for applications requiring precise tolerances, such as cylinder barrels or piston rods. The smooth inner surface also reduces friction and wear, thereby enhancing overall equipment performance and lifespan.In addition to their mechanical properties, Honed Tubes offer excellent corrosion resistance due to their high-quality steel composition. This ensures durability even under harsh operating conditions or exposure to corrosive substances.Honed Tubes are available in various sizes and materials depending on specific application requirements. They can be manufactured from carbon steel, stainless steel, or alloy steel with different grades tailored for different purposes.

06

Honed Tube Application

Honed tubes are precision seamless steel tubes that have undergone a honing process, which involves grinding the inner surface of the tube to achieve a smooth finish.These tubes find extensive application in hydraulic and pneumatic cylinders, where they serve as crucial components for transmitting fluid or air pressure. The honed surface of these tubes provides improved wear resistance, reduced friction, and enhanced sealing properties.In addition to cylinder applications, honed tubes are also used in industries such as automotive manufacturing, construction machinery, mining equipment, and agricultural machinery. They are employed in the production of shock absorbers, telescopic cylinders, steering systems, injection molding machines, among others.

Seamless steel pipe introduction

APPLICATION

Seamless steel pipe Application

Precision steel pipe introduction

Precision steel pipe Application

Honed Tube introduction

Honed Tube Application

R & D TEAM

PROFESSIONAL TEAM

EXPORTING COUNTRY

EXPORTED TO MANY COUNTRIES

RIGOROUS TESTING

HIGH QUALITY PRODUCTS

ONLINE SUPPORT 24/7

SUPPORT ONLINE 24 HOURS

JUST IN TIME DELIVERY

PUNCTUAL DELIVERY

QUALITY QUALIFIED

GOOD QUALITY IS SAFER

2004

was founded on(year)

850

staff members

16

Exporting country

15000

Covering an area of (square meters)

60000

Annual output(tons)

GET IN TOUCH

CONTACT US

Liaocheng Xinglong Seamless Tube Manufacturing Co., Ltd.

CONTACT US